Needless to say, the calculation of units to go in ACM is a bit trickier than how it’s calculated in base Maximo. People who have worked on it can understand where I am coming from.

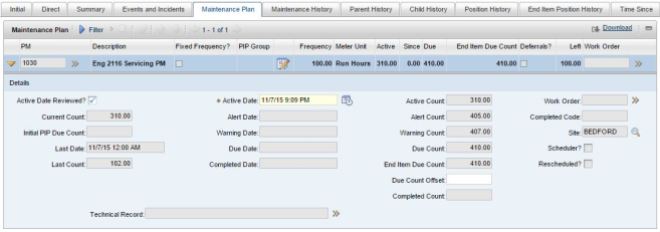

Units to Go is calculated based on the PLUSALFEVENT (Maintenance Event) record which is created when the PM is made ACTIVE. These are the records displayed in the Maintenance Plan tab in the Asset (CM) application.

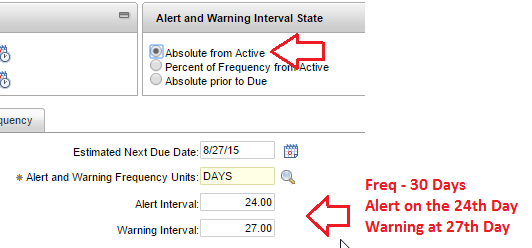

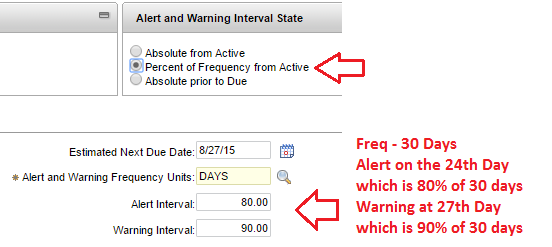

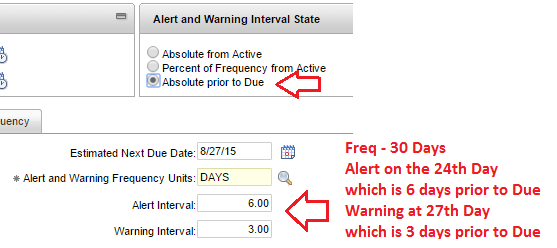

It is these PLUSALFEVENT records that are utilized by the BDI process to decide when Work Orders should be created from the PMs and also to decide whether the PM is overdue, past its warning point etc.

The ‘Left’ value on the Maintenance Plan tab is essentially the units to go for the associated PM in Assets (CM).

The calculation for units to go is:

Units to Go = Due Count – Current Count

Where Due Count = Active Count + PM Meter Frequency

The Active Count is the meter count calculated at the Active Date of maintenance event (PLUSALFEVENT.ACTIVEDATE).

Every time a work order for a maintenance event is completed, a new maintenance event (PLUSALFEVENT) entry is created with an Active Date same as that of the work order completion date. The same date is stamped as inactive date on the old maintenance event record.

So every time the active date from the most recent maintenance event record is used to calculate the Due Count for the PM.

The Current Count is the meter count at the current system date and time.